| Tipos de produtos usados | Pontos de Transferência , Estrutura do Chute |

|---|---|

| [unset] | MartinPLUS® Melhorias |

| Indústria | Usinas Termelétricas |

| cliente | Entergy Operations Services, Inc. Independence Generating Plant, Newark, Arkansas |

Problema

In normal operations, Conveyor 4B, a 72-inch (1800 mm) feeder belt, loads coal onto the 72-inch (1800 mm) belt of Conveyor 5A. Plant engineers wanted to be able to bypass Conveyor 5A and load material directly from Conveyor 4B onto Conveyor 10A. The plant needed engineering assistance to accomplish this redesign and avoid bottlenecks and plugs in the new chute.

Solução

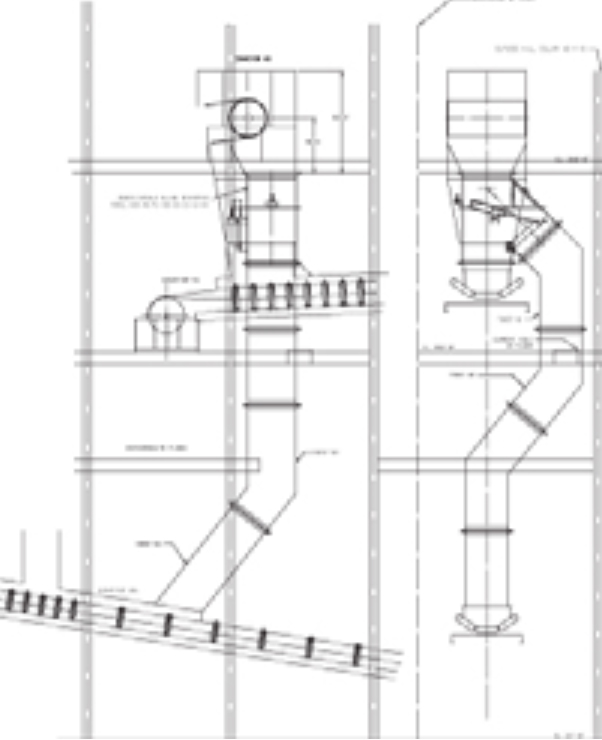

Following a site survey, MartinPLUS® Process Improvement specialists designed a flop gate for installation between Conveyors 4A and 5A. They also developed the chutework to connect the flop gate to Conveyor 10A. This chute required a material drop of about 45 feet (13.7 m) with a lateral offset of approximately 10 feet (3 m).

Martin Engineering prepared conceptual drawings. After plant approval, Martin developed detailed fabrication drawings of all chute work sections for local fabrication and installation.

Resultados

The reengineered chutework fit within 1/16 of an inch (1.5 mm) of desired location. Material flow rate achieves operating goals.

Resolvemos o seu problema!

Com mais de 70 anos de experiência resolvendo problemas em todo mundo com os profisisonais mais experientes e educados em nossas equipes, podemos assegurar-lhe que ficaremos perto o suficiente para saber o que precisa ser feito em seguida e resolver o seu problema.

Deixe-nos lhe mostrar a solução.