110 Air Cannons Installed At Votorantim Cimentos

Publicado: August 17th 2012

[Cuiabá and Rio Branco do Sul, Brazil] — One of the world’s leading manufacturers of cement, concrete and aggregates has specified a total of 110 air cannons to facilitate material flow in two new plants currently nearing completion in Brazil. Starting in the early design stages of the project, Votorantim Cimentos has maintained an intense focus on efficient material flow, with engineers carefully researching the latest technologies to maximize efficiency and reduce maintenance expenses. Company officials anticipate that the cannons, equipped with high-efficiency valves, will prevent blockages that could slow production, while minimizing air consumption.

[Cuiabá and Rio Branco do Sul, Brazil] — One of the world’s leading manufacturers of cement, concrete and aggregates has specified a total of 110 air cannons to facilitate material flow in two new plants currently nearing completion in Brazil. Starting in the early design stages of the project, Votorantim Cimentos has maintained an intense focus on efficient material flow, with engineers carefully researching the latest technologies to maximize efficiency and reduce maintenance expenses. Company officials anticipate that the cannons, equipped with high-efficiency valves, will prevent blockages that could slow production, while minimizing air consumption.

The two new plants are part of a massive R$2 billion investment to enhance production throughout Brazil, and are expected to produce approximately 8,500 tons of clinker per day between them when they come online later this year. In designing the processes, Votorantim engineers wanted to take all reasonable measures to prevent accumulations in vessels and storage systems. They contacted Martin Engineering to conduct an audit of the two processes, and a joint effort was developed to determine the optimum solution, including air cannon design, nozzle selection and specific locations to maintain high throughput.

Air Cannon Operation

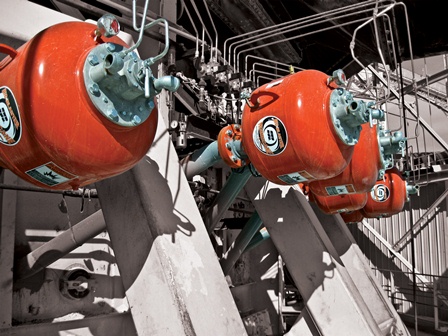

“The two primary components of an air cannon are a high-flow valve and a pressure tank,” explained Martin Engineering National Sales Manager Rodrigo Trevenzolli. “The device performs work when compressed air in the tank is suddenly released by the valve and directed through a nozzle, which is strategically positioned in the tower, duct, cyclone or other location.”

“The two primary components of an air cannon are a high-flow valve and a pressure tank,” explained Martin Engineering National Sales Manager Rodrigo Trevenzolli. “The device performs work when compressed air in the tank is suddenly released by the valve and directed through a nozzle, which is strategically positioned in the tower, duct, cyclone or other location.”

Often installed in a series and precisely sequenced for maximum effect, an air cannon network can be timed or computer-controlled to best suit individual process conditions and material characteristics. Fast-acting valves can release the tank volume in less than 300 milliseconds, creating a high-magnitude force at the exit nozzle which is installed through the wall of the vessel or duct.

The timed discharge breaks down material accumulations and releases blocked pathways, allowing solids and gases to resume normal flow without intervention by maintenance personnel. In order to customize the air cannon installation to the service environment, specific air blast characteristics can be achieved by manipulating the operating pressure, tank volume, valve design and nozzle shape.

Cost of Ownership

One of the primary reasons Votorantim officials selected Martin Engineering for the air cannon work is the low operating cost of the company’s equipment. “Compared to other sources of energy, compressed air is relatively expensive,” Trevenzolli explained. “As energy costs continue to rise, so does the value of cannon technologies that can reduce compressed air consumption.”

Martin Engineering’s newest cannon designs optimize compressed air use by employing advanced valve technology, with more efficient valves mounted on smaller tanks able to deliver higher discharge forces than less efficient valves mounted on larger tanks. The work is performed more effectively by the high-efficiency valve, and the compressed air savings is equal to the difference in tank volumes.

Because larger tanks deliver longer blast durations from the greater air volume being discharged, there’s a temptation to assume that the larger tanks perform more work. Trevenzolli explains the fallacy: “In reality, peak force is generated only during the first few thousandths of a second following the valve opening, so in applications requiring high output force to move material, the duration of useful energy is extremely short. The subsequent discharge of compressed air is actually wasted.”

The new family of positive-action valves from Martin Engineering produces about twice the blast force output of the valve generation introduced just a decade ago, while using about half the compressed air volume. If the two designs were set to deliver the same discharge force, the new valve would operate at about half the pressure of the preceding design. Firing only in response to a positive surge of air, the specially-designed valve allows the control solenoid to be positioned as far as 200 feet (60 meters) from the tank, keeping critical components away from harsh service environments.

After studying the plant designs and potential accumulation spots, engineers from the two companies identified the optimum locations for the air cannons. Crews are now collaborating on the installation of 110 Martin® Hurricane Supreme Air Cannons in the plants, covering preheater towers, additive silos and cyclones. The units will fire a powerful discharge of compressed air in a prescribed pattern to remove material that sticks to vessel walls and ductwork. In the Cuiabá plant, 56 cannons are being installed, with 54 being placed at Rio Branco.

The benefits of specifying the new technology for air cannon networks include reduced energy costs, improved system performance and increased uptime, with greater availability of compressed air for other processes within the plant. All should contribute to a healthier bottom line, justifying the added up-front expense with a payback period that’s far exceeded by the equipment’s expected lifespan.

Votorantim Cimentos was founded in 1936, and currently supplies more than 40 products from 50 different production facilities, located in nearly every Brazilian state. Outside Brazil, VC operates six factories and more than 150 concrete and aggregate units in North America, while maintaining substantial South American investments in Bolivia, Chile, Paraguay, Argentina, Uruguay and Peru.