Publicado: August 2nd 2016

The Büyükçekmece cement plant located west of Istanbul, Turkey, has a production capacity of 5,900 tons of clinker per day. Operated by the Akçansa Group (a joint venture between Turkish Sabanci Holding and German Heidelberg Cement), it’s one of the largest producers in Turkey’s busy cement industry, supplying 10% of the country’s total demand and 12.5% of the nation’s total cement and clinker exports. Originally built in 1967, the facility has three clinker production kilns, providing cement primarily to the Marmara region of Istanbul.

Literally the pioneer in alternative fuel use in Turkey’s cement industry, the Büyükçekmece plant was issued the country’s first license for its process in 2005, the same year that it installed a special self-built tire feeder. The current fuel ratio is approximately 77% pet coke and 23% alternative fuels, including waste oil, refuse-derived fuels (RDFs), tires, industrial plastics and dried sewage sludge.

Accumulation Issue

As the facility’s output capacity increased and fuel types changed over the years, workers began having to manually dislodge material buildup in Cyclone 4 of Kiln #2’s preheater tower in order to maintain throughput. The unscheduled shutdowns to allow cleanout of the cone and deep tube interfered with production schedules and exposed maintenance staff to potential hazards.

These accumulations can be particularly severe when fuels with high sulfur or chloride content are used, such as pet coke and RDF. In extreme cases, massive build-ups can suddenly break loose and suffocate the process, potentially causing significant damage to equipment.

In addition to the necessary cooling time, the cyclone cleanout process required 3-4 people working with jackhammers through access doors for several hours while they battled the heat and dust. Additional energy was required to re-start the process and get it back up to operating temperature. Unfortunately, even after expending all that time and energy, the accumulation became so severe that the problem would typically return within a week, choking off the material flow and forcing yet another shutdown. Plant officials contacted Martin Engineering Turkey to conduct an audit of the process, and a joint effort was developed to determine the optimum solution.

A Proven Approach

Upon completion of the audit, it was determined that a series of air cannons would be the best option to return normal flow to the system and prevent future blockages. Air cannon technology has a long history of service in cement processing, helping to improve material flow and reduce build-up. The timed discharge of a directed air blast can prevent accumulation that impacts process efficiency and raises maintenance expenses, while helping manufacturers to minimize the need for process interruptions and manual labor.

The two basic components of an air cannon are a fast-acting, high-flow valve and a pressure vessel (tank). The device performs work when compressed air in the tank is suddenly released by the valve and directed through a nozzle, which is strategically positioned in the tower, duct, cyclone or other location. Often installed in a series and precisely sequenced for maximum effect, the network can be timed to best suit individual process conditions or material characteristics.

The air blasts help break down material accumulations and clear blocked pathways, allowing solids and/or gases to resume normal flow. In order to customize the air cannon installation to the service environment, specific air blast characteristics can be achieved by manipulating the operating pressure, tank volume, valve design and nozzle shape.

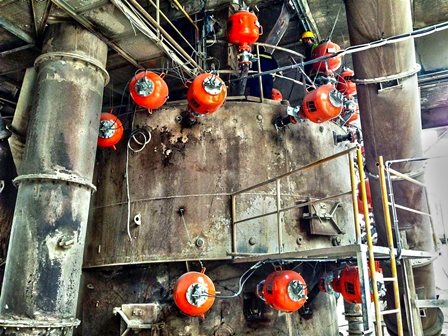

Engineers from the two companies met to discuss details, including air cannon design, nozzle selection and specific locations to maintain optimum material flow. To control the material buildups and maintain production stability, 29 Martin® Hurricane Air Cannons were supplied by Martin Engineering Turkey, each with a 70 liter reservoir, installed in strategic locations by a MartinPLUS® Service Team.

The installation included hi-velocity and fan-jet nozzles with Martin® Thermo Safety Shields to protect maintenance personnel when they inspect or service the air cannon system. Also known as blast guards, Martin® Thermo Safety Shields are situated between the process and the air cannon valve itself. Available in manual or air-operated models, these devices help prevent material backflow during service and shield the air cannon valve components from material spray.

The new air cannons were arranged in three groups, each directed by the plant’s control room. The discharge sequence moves upward in a spiral, with cannons firing 10 seconds apart. The entire 80-90 second cycle typically repeats approximately every 20 minutes, but operators have varied the time from 5-45 minutes, depending on specific operating conditions.

Since the installation of the new air cannon network, no unscheduled shutdowns have been caused by material buildup in that section of the cyclone. With the problem solved, engineers have turned their attention to some additional buildups higher in the deep tube, an area not covered by the air cannon network. During its next shutdown, the plant will install an additional set of four Martin® 70L Hurricane Air Cannons, locating them above the cyclone deep tube.

Cost Reduction

The audit also revealed an opportunity to reduce the operating cost of the facility’s 22 existing Martin® Tornado Air Cannons at the inlet chamber and riser duct of the Kiln #2 preheater tower by upgrading each one with a Martin® Piston Return Reservoir, a canister that closes the valve after approximately 50% of the volume has been discharged. The reservoir is a pneumatic device that collects the exhaust air from the valve and redirects that pressure to close the piston when the valve & tank pressure equalize.

When equipped with a piston return reservoir, the air cannon produces an initial blast force of the same strength, but the duration of the discharge is reduced. Instead, the air retained inside the cannon’s tank minimizes the overall air consumption without reducing initial output force. Since the main air tank is never completely evacuated, the volume of air required to refill after each discharge is reduced. With the air cannon’s peak force unaffected, the same amount of work can be accomplished with half the amount of compressed air.

Before the installation of the return reservoirs, the air consumption of the 22 Martin® Tornado Air Cannons at Büyükçekmece was estimated at 2 cubic meters per minute, or an annual total air consumption of approximately 525,600 cubic meters. If the cost of service air is estimated at two cents per cubic meter, the total air cost would be $10,512 per year. After installation of the reservoirs, the annual air consumption has been reduced to 262,800 cubic meters, while retaining the same air cannon performance. If the minimum lifetime of an air cannon is estimated at 10 ten years (not an unreasonable prospect), the cost savings over that period would be $52,560.